Create a symbiotic relationship with the environment and your community.

Our clients are pushing the boundaries of how they connect with the natural environment and the communities they build. We are empowering them to create vibrant environments through biophilic designs that are consistent with the principles they have established for their company or lives.

Integrating mass timber and architectural fabric membranes through our process where each project is planned, developed, and assembled with the environmental, psychological, social, and physical impacts as a core priority.

Tridome Structures is INVITING YOU on a journey…

The construction industry is changing; fading are the days of on-site fabrication and construction, making way for a more reliable and efficient model of on-site assembly. Collaborative and inclusive planning from a comprehensive team of designers, professional project managers, manufacturers, erectors/assemblers, and trade professionals working closely together will ensure you are setting up your project for success in the modern landscape of how we build.

Holistic Planning

A rewarding journey starts with a great plan.

At Tridome Structures, all of our projects commence with a unique and holistic approach. Traditional firms delegate responsibilities from profession to profession, frequently resulting in communication and execution problems. Every craft or profession that can be a part of the project will be expertly represented from the beginning, from the architect with the big ideas to the team who implements the finishing touches. Integrating our step by step holistic planning the projects are no longer stalled by the discovery of a misplaced beam, poor choice of material resulting in a change order or sub trades unable to complete their work due to an obstacle.

What are the benefits of holistic planning?

Up to a 30% reduction in on-site construction time

Risk and deficiencies mitigation improvements

Material sourcing and supply chain impact prioritization

Improved mental and physical health of all parties involved

Greater ROI

Embodied carbon management

Integrated end-of-use planning and provisions

Economize operating and maintenance cost

Progressive + Conscious Development

Thoughtfully procured supplies and well executed development are the key to a successful journey

The gradual and deliberate creation of the goods, packages, and processes for your newly established plan guarantees that the efficiency, values, and savings outlined are not lost or neglected. When done correctly, this technique allows for even larger gains in EPSP impacts and can set your project apart from the competition.

This saves you time, money, and potential grief. Progressive and conscious development for us also means using materials that are environmentally sustainable, so you not only receive a well built and long lasting structure, but are also helping improve the health and longevity of your community.

Overview of our development style’s benefits:

Materials that are sustainably sourced

Little to no waste, as all materials are specially ordered and produced

Workplace improvements, reduced weather days, improved safety, control and predictability

Community

Increased ROI and realized savings

Supply chain management and

Leveraging multiple manufacturers and suppliers

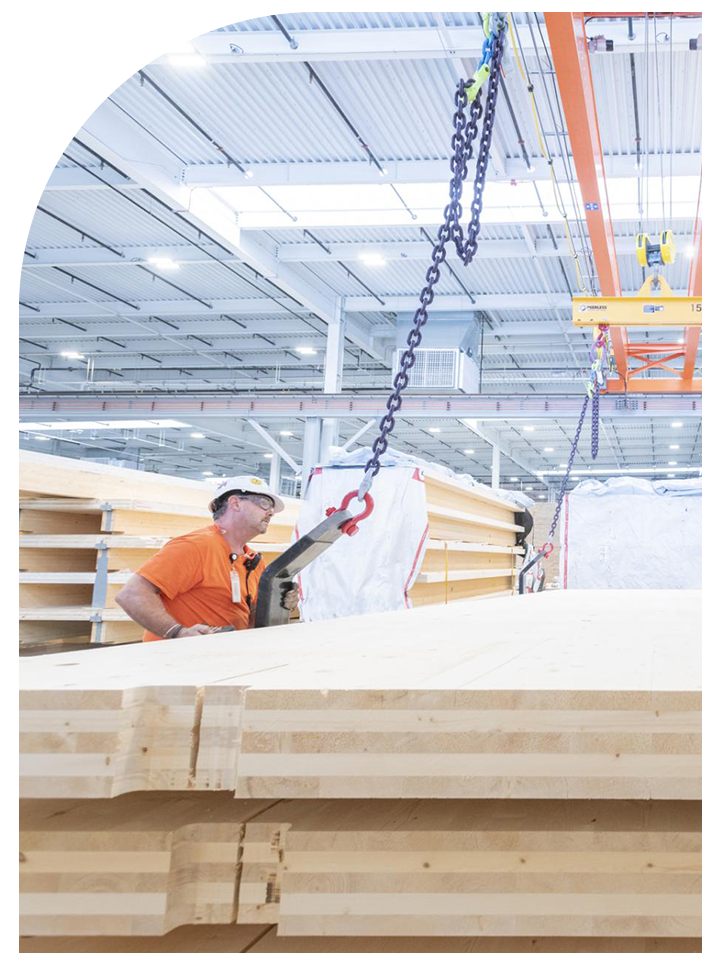

Innovative Assembly

Putting it all together has never been easier

Innovative assembly is the final step in turning your dream project into a reality. Once everything has been prepared in the development stage, all elements are shipped to the building site for an assembly that is faster, more organized, and better for the environment than traditional building practices.

Because the majority of the project has been built elsewhere, our construction method does not involve the wasteful and environmentally damaging practice of over-clearing the construction site for staging and storage. Less time spent on-site reduces noise, air, and water pollution, as well as greenhouse gas emissions caused by habitat destruction and the use of heavy machinery.

Where are the gains in assembly over fabrication on site:

Reduced site congestion

Strategic equipment utilization

Lowered site waste and debris

Decreased build time

Controlled timelines

Effective simplified organization

Lowered embodied carbon

Overall improved project experience

Thoughtful Legacy

Our buildings have a planned life-cycle.

At Tridome Structures, we not only build differently, but we plan for what comes next. While creating our structures, we take into account the legacy your structure will have on your community and the environment. Our structures are designed so that they can both stand the test of time and, if need be, be moved, divided, or repurposed in order to evolve with you. Additions and expansions can be integrated seamlessly, and if our structures are no longer what you need, they can be recycled. Our fabric membranes are made solely from recyclable materials, while our mass timber can be turned into useful biofuel or be decomposed naturally, easily returning to where it came from: the Earth.

Benefits of investing in structures that plan for the future:

Reduce waste in landfills

Peace of mind

Opportunity for growth

Adaptable

Reduce environmental impact

Greater return on investment over the entire life cycle

Optimized

Let’s talk about your project.

What People Are Saying

Erin at Tridome Structures was instrumental in helping us make a decision whether to use a tension fabric structure or steel building for storage and farm use.

She provided a reasonably priced well constructed product, prompt and courteous customer relations and she stands behind their product.

I am happy overall with our building as well as the service and support provided by Erin and Tridome Structure.

— Mallory Everton, ON

I was not initially responsible for hiring Tridome Structure for our project, but I have since and will continue to use them in the future. Our situation was unique because they were a sub-contractor brought on to fix other errors and issues. TJ came in and was not given all the information regarding erection phasing and details, but he took the time to listen and worked with me. TJ and his team turned a project that could have gone sideways quickly back on track and helped make up lost time.

Bringing Tridome on from the start would eliminate many potential issues as the project progresses. Once organized, they get a lot done in a short amount of time, pay attention to details, and take pride in their work.

— Kevin G. PMP GC

Why Us?

The right materials, the right plan, the right reasons.